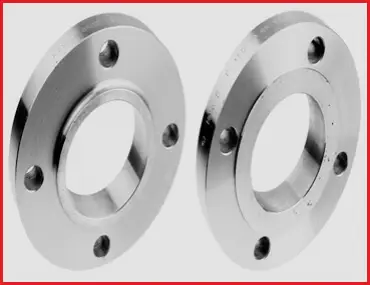

Slip On Flanges

Slip on flange are slipped over the pipe and welded (generally both inside and outside) to give quality and prevent spillage. Slip on Flanges are at the minimal effort end of the scale, and don't require high precision when slicing the pipe to length. These slip on can here and there have a manager or center point, and can be made with a drag to suit either pipe or tube.

Specification of Slip On Flanges

| Type: | SO Forged Flange |

|---|---|

| Material: | ASTM A105/A105N

ASTM A182 : F304, F304L, F316, F316L, F317L, F310, F321, F321H, F347, F347H, F44, F1, F5,F9, F11, F22, F91, F51, F53, F55, F904L ASTM A350 : LF-1, LF-2, LF-3 ASTM A694 : F42, F46, F48, F50, F52, F56, F60, F65, F70 ASTM B564 : C-276, C-22, B-2, C-4, INCONEL 600, 601, 625, 800, 800H, 825 ASTM B462 : Alloy 20 ASTM A516 : 60, 65, 70 ASTM B151/B171 : Alloy 90-10 (UNS C70600) & Alloy 70-30 (UNS C71500) |

| Standard: | ANSI,JIS,DIN,BS,EN,GOST |

| Size: | 1/2-60 inch (DN15-DN1500) |

| Pressure: | ANSI class 150,300,600,900,1500,2500,PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160 |

| Packing: | No Fumigate or Fumigate Plywood/Wood Pallet or Case |

| Surface Treatment: | Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized. |

| Usage: | Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc. |

Faqs

A slip on flange is a type of pipe flange that allows the pipe to slip inside the flange before welding. It is welded both inside and outside to provide strength.

They are mainly used in low-pressure, low-temperature applications such as water lines, cooling systems, and fire-fighting pipelines.

They are produced in carbon steel, stainless steel, alloy steel, and other special alloys depending on the application.