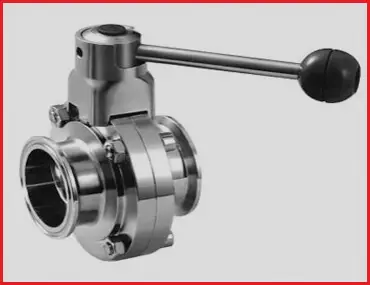

Butterfly Valves

Our company makes one of the finest Butterfly valves,which can be used for special applications like isolation, throttling and control. Butterfly valves are suitable for fluids like air, water, toxic gases, vaccum, acid, chemicals, LPG, slurries & combination of gases and solid.

Salient Feature

- Meets manufacturing standard design as per BS 5155/ API 609 / IS 13095 AWWA C-504 /ANSI B 16.34 and inspection testing standard as per API 598/ BS 6755 / MSS - SP -61.

- SPLIT body compact design for open/close cycle with very low torque.

- 2PC SPLIT body with replaceable PTFE seat type valves can be supplied on specified request.

- Multipurpose water design.

- REPLACEBAL/ Molded rubber seat in various material.

- 100% tight shut off in both flow directions.

- A fully universal body design ensures suitable for mounting between all popular standards (VIZ: - ANSI, BS, DIN, IS, JIS, etc.)

- Lower torque requirement because of bearing support to the shaft.

- The notch disc & band lever ensures locking of the valves in 8 intermediate positions in addition to close and open position.

Option

- Log type body design available on request.

- Flanged end design butterfly available on request.

- Valves can be opened by manual gear unit or pneumatic /electrically actuator.

- PTFE lining / coating.

- Valves can be supply with PTFE lining /coating in corrosive application.

- Ring joint facings available in higher classes.

- Body & disc supply in difference M.O.C such as CI -IS 210 GR. FG- 200, SG IRON GGG 40, ASTM A 216 GR. WCB, ASTM A 351 GR CF8 / ASTM A 351 GR CF8M

- Seat supply in difference M.O.C. such as 1) nitrile 2)epdm 3) hypalon 4) silicon 5) viton 6)neoprene

- Stellited seating hard facing are provided on requestOffset disc design available in 350 NB above size butterfly valves.

- High performance metal to metal contact valves for high temperature application for hot gases.

Material of Construction

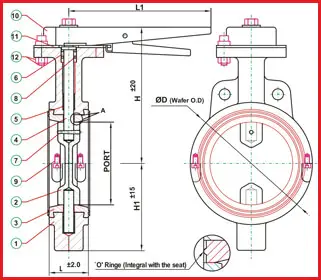

| P. No | Qty. | Nomenclature | Material |

|---|---|---|---|

| 1 | 1 | BODY | CI. IS 210 Gr. FG 200 /WCB /CF8 /CF8M |

| 2 | 1 | DISC | CI. IS 210 Gr. FG 200 /WCB /CF8 /CF8M |

| 3 | 1 | SEAT ( REPLACEABLE ) | NITRILE /NEOPRENE/ EPDM / HYPALON / VITON/PTFE |

| 4 | 2 | STEM | AISI 410 / AISI 304 / AISI 316 |

| 5 | 2 | BEARING BUSH | BRASS / STAINLESS STEEL- PTFE |

| 6 | 2 | BUSH | PTFE/POLY ACETAL / NYLON |

| 7 | Req | TAPER PIN | S.S. 304 / S.S. 316 |

| 8 | 3 | ‘O’ RINGS | NITRILE/NEOPRENE/ EPDM/VITON |

| 9 | Req | BODY CLAMP. CAP SCREWS | CARBON STEEL / S.S. 304 |

| 10 | 2 | BOILS & NUTS | CARBON STEEL |

| 11 | 1 | NOTCH DISC | CARBON STEEL |

| 12 | 1 | LEVER | CARBON STEEL- FABRICATED |

Technical Specification

| Manufacturing | BS 5155 / API 609 / IS 13095 |

|---|---|

| Face to Face(WAFER SHORT) | BS 5155 / API 609 (CATEGORY A ) / IS 13095 |

| End Connection | WAFER TO SUIT ANSI B16.5 150# / DIN 2542 (PN-10) DIN 2543 (PN-16) / Bs10 TABLE E |

| Inspection & Testing Std | BS 5155 / BS 6755 (part-1) / API 598 / IS 13095 |

Faqs

A butterfly valve is a quarter-turn valve with a disc that rotates around a central axis to start, stop, or regulate fluid flow.

They are widely used in water treatment, HVAC systems, chemical processing, fire protection systems, and pipelines for large diameter flows.

Yes, they can be used for flow regulation, but they are less precise than globe or needle valves.